SOUTH EAST USA WHEELS EVENTS-Car and Motorcycle Events Calendar

Your Free Internet Calendar For All Events On Wheels

-

Labeling Machine

- Gadsden, AL

- United States

- Share on Facebook MySpace Tweet

- Blog Posts

- Discussions

- Events

- Groups

- Photos

- Photo Albums

- Videos

RSS

When to Upgrade vs Replace Packaging Equipment: A Practical Guide for Growing Plants

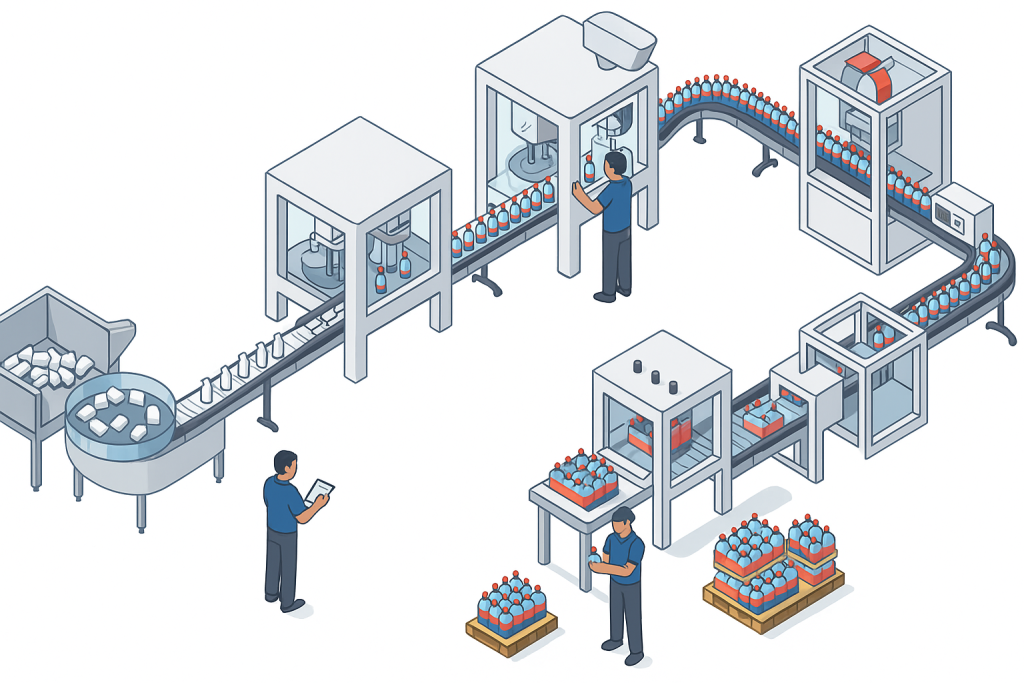

Growth is a good problem to have—but for manufacturing plants, growth often exposes hard limits in existing packaging equipment. Many operations reach a point where output targets, quality standards, and operational reliability begin to conflict with aging or undersized systems. The critical decision is no longer whether to invest, but whether to upgrade existing assets or replace them entirely.

This decision has long-term consequences for uptime, capital allocation, and scalability. Making the wrong call can stall growth or force premature reinvestment. This guide explains how growing plants can make that decision using engineering and operational signals—not guesswork.

When an Upgrade Makes Sense

Upgrading is appropriate when the core mechanical structure remains sound, but specific limitations are preventing the line from keeping pace with demand.

Indicators that an upgrade is viable

- The frame and drive systems are structurally reliable

- Controls are outdated but replaceable

- Output shortfalls are moderate, not structural

- The equipment supports current container formats

Upgrades commonly involve controls modernization, automation add-ons, or changeover improvements that extend the useful life of the packaging machine without requiring full replacement.

Typical upgrade scenarios

| Limitation | Upgrade Action | Result |

|---|---|---|

| Manual adjustments | Servo or tool-less conversions | Faster changeovers |

| Inconsistent timing | Controls retrofit | Improved stability |

| Labor dependency | Automation modules | Reduced intervention |

| Minor speed gaps | Drive optimization | Incremental throughput |

An upgrade approach preserves capital while buying time—provided the underlying design can support future demand.

When Replacement Is the Better Decision

Replacement becomes unavoidable when equipment design limits cannot be engineered around. This is especially common in plants that have outgrown their original capacity assumptions.

Signals that replacement is required

- Structural vibration at higher speeds

- Inability to integrate modern controls

- Frequent downstream bottlenecks

- Compliance or safety limitations

At this stage, continued upgrades create diminishing returns. Replacing aging packaging machinery allows plants to reset performance baselines and design for the next growth phase instead of chasing the last one.

Throughput vs Stability: The Core Trade-Off

Growing plants often chase speed, but speed without stability introduces risk. The decision to upgrade or replace should prioritize sustained throughput, not peak output.

Stability comparison

| Factor | Upgraded Equipment | New Equipment |

|---|---|---|

| Peak speed | Moderate | High |

| Sustained output | Variable | Predictable |

| Downtime recovery | Slower | Faster |

| Scalability | Limited | Designed-in |

Plants that rely on a single filling machine, labeling machine, or capping machine often discover that isolated upgrades solve only part of the problem. System balance matters more than individual performance.

Scalability: Designing for

…

The post appeared first on Accutek Packaging Machine Equipment.

6 Packaging Machinery Selection Mistakes That Cost Manufacturers Millions (and How to Avoid Them)

Packaging machinery decisions are rarely reversible—and the wrong choice can quietly drain millions from a manufacturing operation over time. From chronic downtime and labor inefficiencies to quality failures and forced re-investment, most packaging losses do not come from machine breakdowns. They come from selection mistakes made long before equipment is installed.

Manufacturers in food, beverage, cosmetics, pharmaceuticals, and chemicals face increasing pressure to scale faster, meet compliance requirements, and maintain consistent output. Yet many still approach machinery selection as a purchasing exercise rather than an engineering decision.

This article breaks down the most expensive packaging machinery selection mistakes and explains how manufacturers can avoid them through smarter evaluation, system-level thinking, and engineering-led planning.

Mistake #1: Buying for Speed Instead of Throughput

One of the most common—and costly—errors is selecting packaging machinery based solely on maximum rated speed.

Machine brochures highlight bottles per minute. Real-world production exposes a different metric: sustained throughput.

Why this mistake is expensive

- High-speed machines amplify upstream and downstream weaknesses

- Minor jams cause cascading line stoppages

- Operators slow machines down to maintain stability

Speed vs Throughput Reality

| Selection Focus | What Buyers Expect | What Actually Happens |

|---|---|---|

| Maximum BPM | Faster output | Increased downtime |

| Isolated machine speed | Higher capacity | Line imbalance |

| Peak performance | Production gains | Operator intervention |

| Minimal evaluation | Lower upfront cost | Higher long-term losses |

How to avoid it:

Evaluate packaging machinery as part of a balanced line, not as a standalone speed upgrade.

Mistake #2: Treating Filling, Capping, and Labeling as Separate Purchases

Many manufacturers source filling machines, cappers, and labelers independently—often from different suppliers. While this may reduce upfront cost, it introduces integration risk that compounds over time.

Where costs accumulate

- Conveyor mismatch and backpressure issues

- Inconsistent machine communication

- Increased changeover time

- Multiple service vendors and spare parts inventories

Integrated vs Fragmented Line Impact

| Factor | Fragmented Line | Integrated System |

|---|---|---|

| Line synchronization | Manual | Engineered |

| Downtime recovery | Slow | Predictable |

| Changeovers | Labor-heavy | Streamlined |

| Long-term scalability | Limited | Designed-in |

How to avoid it:

Select packaging machinery with system-level engineering compatibility, even if machines are purchased in phases.

Mistake #3: Ignoring Product & Container Variability

Packaging machinery that performs well on one SKU can struggle—or fail—when products change.

Common overlooked variables include:

- Viscosity changes across product lines

- Foaming or aeration

- Container tolerances

- Label material variation

Cost of ignoring variability

- Excessive scrap

- Rework and relabeling

- Lost production during adjustments

- Premature equipment replacement

Product-Driven Selection Checklist

| Variable | Must Be |

|---|

…

The post appeared first on Accutek Packaging Machine Equipment.

Labeling Machine's Page

Profile Information

- Non-business Name or Alias?

- catherine

- What are your other interests?

- writting

Birthdays

Birthdays Today

Birthdays Tomorrow

Blog Posts

A Bite of History: Current Value Trends for Brass Era Cars (1896–1915)

A Bite of History - By Mike Thies

Current Value Trends for Brass Era Cars (1896–1915)

Over the past decade, values for Brass Era automobiles (1896–1915) have followed a familiar but revealing pattern. The late 2010s saw steady appreciation as collectors sought early, historically significant cars with craftsmanship that…

ContinuePosted by Chuck Aaron on January 13, 2026 at 10:43am

A Bite of History - Waffle House by Mike Thies

A Bite of History by Mike Thies

Waffle House

Waffle House has a long-standing partnership with Richard Petty, featuring a custom Waffle House paint scheme on the No. 43 Ford. This connection to the racing world naturally bleeds into the broader car collector community. Waffle House is a staple for 'Cars and Coffee' style meetups. Because they are open 24/7 and located…

ContinuePosted by Chuck Aaron on December 25, 2025 at 6:37am — 1 Comment

© 2026 Created by Global Wheels Events.

Powered by

![]()

Comment Wall

You need to be a member of SOUTH EAST USA WHEELS EVENTS-Car and Motorcycle Events Calendar to add comments!

Join SOUTH EAST USA WHEELS EVENTS-Car and Motorcycle Events Calendar